Polyethylene Naphthalate — A new-generation, high-performance polymer

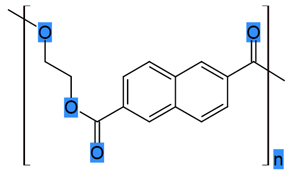

Polyethylene Naphthalate (PEN) (Poly(ethylene 2,6 naphthalate) is a new generation polyester polymer of naphthalene-2,6-dicarboxylate and ethylene glycol, exhibiting outstanding heat resistance and improved dimensional stability. Although PEN is more expensive than polyethylene terephthalate (PET), PEN's physical properties are superior to those of PET and its demand is expected to increase in the future.

|

acid process, named according to whether the starting monomer is a diester or a diacid of naphthalene, respectively. In both cases, the glycol monomer is ethylene glycol.

Benefits and applications of PEN

PEN exhibits higher dimensional stability, shrinkage resistance, temperature stability and better barrier properties than PET. Owing to its superior modulus of stiffness, PEN can be used to produce films of equivalent strength to PET but at a significantly lower thickness and narrower width. Such films are advantageous for electrical, flexible food packaging and imaging applications. Other applications for PEN films include thermal sheets, pressure-sensitive tapes and solar cell protection.

The good barrier properties of PEN make it suitable for bottling beverages susceptible to oxidation, such as beer bottles. Norway's Association of Brewers and Soft Drink Producers have introduced PEN beer bottles, which exhibit the durability needed for multiple refilling cycles, the capability to withstand multiple high-temperature washes, and the barrier properties required for extended shelf life. Currently, about 5 million new bottles are in circulation and the number is expected to increase as consumers start developing preference for the light-weight, shatter-proof bottles. Furthermore, consumers in other countries such as Denmark also typically prefer PEN bottles over glass for beer.

PEN's anti-scalping properties make it safe for food-contact applications. Tableware made from PEN can withstand rough handling and multiple high-temperature washings while preventing endocrine extraction into food. In Japan, Teijin Chemical Ltd. and Sanshin have introduced PEN tableware for school cafeterias. PEN is used to make high-performance sailcloth and PEN films are also used to laminate sails on boats owing to the excellent UV resistance of PEN against loss of mechanical properties. In addition to improved resistance against deterioration of mechanical properties by sunlight, PEN films provide greater tensile strength and modulus, allowing a 10% reduction in sail weight, as compared to PET films.

The use of PEN resin in tyres adds rigidity to the tyre and reduces road noise by as much as 30 percent. PEN's compression characteristics also help produce a more comfortable ride. These performance enhancements make the tyres ideally suited for high-end luxury cars. PEN's higher dimensional stability as compared to plastics like nylon and rayon, allows its use in the manufacture of light-weight tyres. Renowned tyre company, Bridgestone, produces its Regno GR7000 tyre with tyre cord manufactured from PEN resin. Interest in the use of PEN in ropes and cables has also increased as oil drilling is now performed in ever deeper seas and depths of up to 3000 metres are being conceived of. PEN possesses higher initial stiffness than PET, which allows its use in mooring ropes and cables for off-shore oil platforms. Such cables are much lighter than traditional steel cables or chains.

PEN use in flexible food packaging not only improves barrier properties but also enables simplification of the packaging structure by reducing the number of required layers, which in turn reduces overall system cost. PEN packaging films can either be metalized or coated with silicon or aluminium oxides. Metalized PEN films show effectively no shrinkage at temperatures up to 200°C.

PEN films are also used in magnetic storage media, photographic imaging, electrical/electronic applications, flexible printed circuit Boards (FPCBs), capacitors, adhesive tapes, voice coils, solar cells and membrane switches and sensors.

Thus, PEN can be tailored to meet the needs of a wide variety of potential end uses and environments.

Roadblocks in the commercialization of PEN

Although PEN was first synthesized in 1945, it has been available commercially only since 1990. Interest in PEN outside of specialized applications has been limited owing to short feedstock supply. 2,6-NDC, a feedstock for PEN, is a challenging chemical to manufacture in polymer-grade quality at a reasonable cost. Until recently, NDC could be obtained only in semi-commercial quantities at a high price.

Recently, with the availability of monomers for poly(ethylene naphthalate) (PEN) at a large scale and low cost, the market for this product has grown in the Asia-Pacific region. However, there are no manufacturers of PEN in India. PEN is more expensive than PET at this point of time and it can be said that such specialty polyester will take time to find a market in the country, and even more time for someone to setup a manufacturing facility for such polyesters.

END

For further information, commentary and interviews, please contact us on +(91-22) 61772000 and info@polymerupdate.com

ABOUT POLYMERUPDATE

POLYMERUPDATE is India's leading plastics and petrochemical intelligence provider. For over a decade POLYMERUPDATE has been a world renowned provider of Petrochemical Market

Intelligence through real time news and price alerts with subscribers based in over 55 countries.

POLYMERUPDATE is the world's first to develop BlackBerry, Android, iPhone & iPad applications thereby achieving its goal of empowering every Smartphone owner with polymer market industry feeds while on the move.

Visit POLYMERUPDATE on the internet at www.polymerupdate.com

Sign up for our newsletters

More like this

The European Debt Crisis - What transpired and what can be expected — by Lekhraj Ghai Read More

Importance of PVC in Indian Petrochemical Industry — by Lekhraj Ghai Read More

The Aftermath of the Intensified Iran Sanctions Read More

Clintons' visit and India's dilemma Read More

Bio-based plastics: A market researcher's viewpoint Read More